PP TATREN IM 45 54 is characterised by very high stiffness and good impact resistance. Outstanding stiffness over conventional impact copolymer gives potential for reduction in wall thickness or increase in top load while stiffness of the article remains the same. Very high Tc helps you to shorten the cooling time and increase production efficiency.

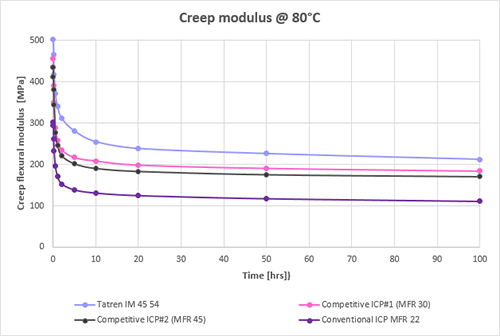

Measured results of creep modulus clearly confirm excellent potential for hot filled stackable products. Performance of the new grade TATREN IM 45 54 after long term of static load was significantly better than conventional ICP grade and better than competitive grades especially at increased temperature.

©2018 MOL Group. You may not copy this document to a web site. MOL Group does not guarantee the typical (or other) values. Analysis may be performed on representative samples and not the actual product shipped. The information in this document relates only to the named product or materials when not in combination with any other product or materials. We based the information on data believed to be reliable on the date compiled, but we do not represent, warrant, or otherwise guarantee, expressly or impliedly, the merchantability, fitness for a particular purpose, suitability, accuracy, reliability, or completeness of this information or the products, materials, or processes described. The user is solely responsible for all determinations regarding any use of material or product and any process in its territories of interest. We expressly disclaim liability for any loss, damage, or injury directly or indirectly suffered or incurred as a result of or related to anyone using or relying on any of the information in this document. There is no endorsement of any product or process, and we expressly disclaim any contrary implication.